One question that is guaranteed to stump even the most experienced IT person is, “when does a printer or copier’s toner need to be replaced?”

It seems like an easy enough question to answer. Once the “toner running low” alert flashes on, it’s time for a new cartridge, right? Not quite.

There are several factors to consider before making the switch — and understanding exactly what these factors are can save your business a surprising amount of money. In fact, trying to manage toner and ink yourself might be the most ineffective route to go.

When to Change the Toner

If you don’t have a managed print partner, it’s up to you to know when to replace your office printer’s toner. Most of the time, the default setting alerts users when toner supplies are running low. Usually, this goes off when about 10%-20% of the toner supply remains.

This little reminder is helpful, but it’s often not the most financially sound advice for your machine. That’s because, depending on the printer and the type of toner cartridge, there could be thousands of pages or months of toner remaining before it's truly empty.

If you have a fleet of printers, a Managed Print Service (MPS) can use Print Monitoring Software to send the right supplies just when its needed directly to the correct copier, MFP or printer. This Just-In-Time inventory strategy makes sure that no excess toner is being purchased and ensures that your inventory is being properly rotated.

How Just-in-Time Works

When a supply reaches a predetermined level, based on an algorithm that factors in both toner coverage and print volume, on a particular device, the MPS team gets a notification that a replacement needs to be sent. The next day, the supply gets delivered with a label that identifies the exact location and point of contact to whom it should be delivered. Supplies are delivered according to the specifications and needs of each model.

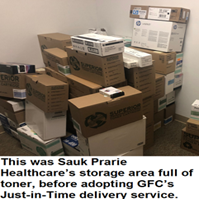

Even better, a Just-in-Time strategy means you don’t have to buy and stock toner yourself, which can mean you have piles of toner around the office to track and inventory. Instead, toner inventory is managed through a local service and distribution center and delivered as needed. You will not need to store or manage an inventory of your own.

Knowing When to Make the Switch

Just-in-Time (JIT) deliveries can be set based upon your typical volume and remaining toner in your device. This means you can choose when to replenish a machine based on actual need, not just when the “low toner” light starts blinking.

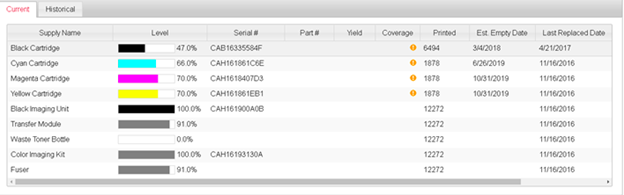

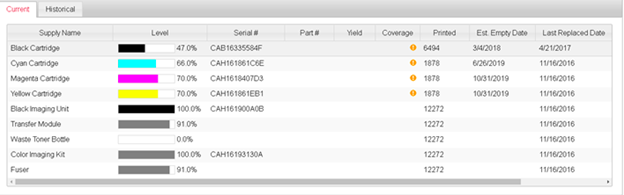

As you can see below, we use FMAudit to automatically track toner levels remotely and to notify our team when one of the monitored devices reaches a predetermined toner level. Auto toner replenishment would be based upon a “days to empty” calculation and shipped out directly to that machine’s location. The toner will have a label with that information, so it gets to the right place at the right time.

Sample Supply Data

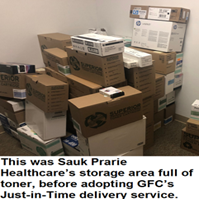

How does Just-in-Time save money? Consider the case of one of our customers, Sauk Prairie Health Care. This fast-growing healthcare company has been able to eliminate its stockpile of toner and supplies thanks to this service, including a 4-foot by 4-foot pile of old toner and supplies that had been taking up space at the company’s headquarters.

Using remote monitoring software for real-time status reporting of all networked devices allows an IT administrator to view device status from a single web portal. Email alerts can also be set up for various device errors. That means not only are you resupplied on time, but those specific errors can be used by technicians to be prepared before they even walk in the door. It will also alert them if it is time to upgrade firmware or other software issues that may be causing problems.

Over the years, we have seen that remote monitoring allows for the most efficient and cost-effective delivery of toner and supplies. If you’d like to learn more about GFC's Just-in-Time Toner Replenishment Program or how our Managed Print Service can help your company, reach out to us today for a free assessment.