In the past, whenever a commercial printer needed maximum speed and volume, the answer was generally a continuous-feed printer. With giant rolls of paper feeding the machine at top speed, cut sheet printers simply couldn’t keep up.

However, the landscape is changing, with cut sheet printers offering more speed and flexibility than ever before. Meanwhile, some continuous roll devices are offering improved resolution and quality than was previously available. In this changing world, what does a commercial printer need to know about choosing the right cut sheet printer?

Here’s what production printing pros need to know about cut sheet versus continuous feed devices.

PRINTING SPEEDS AND FEEDS

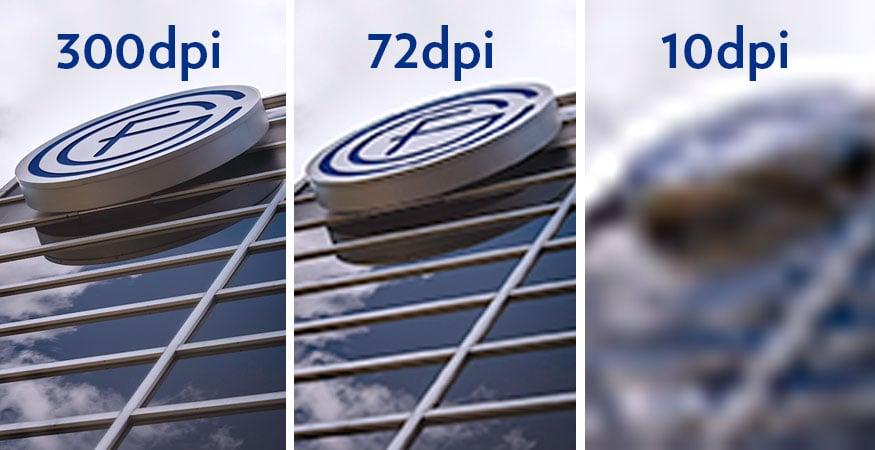

According to industry research from InfoTrends, the average continuous or roll-fed systems can handle up to 40 million impressions a month at speeds of up to 1700 pages per minute (ppm). Meanwhile, the average cut sheet devices offer speeds of up to 130 pages per minute but print quality of up to 4800 dots per inch (dpi).

These numbers illustrate why devices in the cut-sheet category are used for low to mid-volume short-run, quick turnaround or print-on-demand work, while continuous-feed devices meet the needs of high-volume printers.

The Evolution of the Cut Sheet Printer

New, lower-cost devices make it more affordable for commercial printers to deliver production-level output quality and reliability with cut-sheet printing machines. New cut sheet machines may still be slower, but speeds are improving while delivering a finer quality and detail.

Cut-sheet workflows are inherently more flexible than roll-fed ones, since more than one stock is easily available from multiple drawers available in a cut-sheet device. In addition, any one job can be printed on different stocks, cover sheets or dividers can be inserted, and finished jobs can be taken directly from the output tray and delivered to a customer. Continuous roll devices require more time to cool and be cut after the prints are made.

In addition, the volume and range of required substrates can make would be difficult to execute with roll-fed devices. A cut-sheet inkjet device brings a strong level of application flexibility to on-demand and just-in-time production workflows, at cost levels that can be very competitive.

When considering a high-speed, high-volume printing solution, it is important to consider the different investment to be made in inkjet or toner-based devices. A toner-based system is faster than an inkjet and delivers very high resolution. Inkjets are invariably slower and require more time to dry or cure, but offer more flexible printing options.

Print service providers, particularly those printing applications like financial records, direct mail and books should consider whether the speed, running cost, and productivity of a continuous feed machine are a good fit. When choosing a cut sheet or continuous feed machine, think about how much document preparation is needed, what substrates, feeding, finishing, and fulfillment you will need. In assessing print quality, be sure that the system has the tools to assure color quality and accuracy, as well as consistency over time for your most demanding jobs.

If you need help deciding on which paper feeding technology you need, and whether modern cut sheet technology can answer the call, talk to the production printing experts at the Troyka-TC.